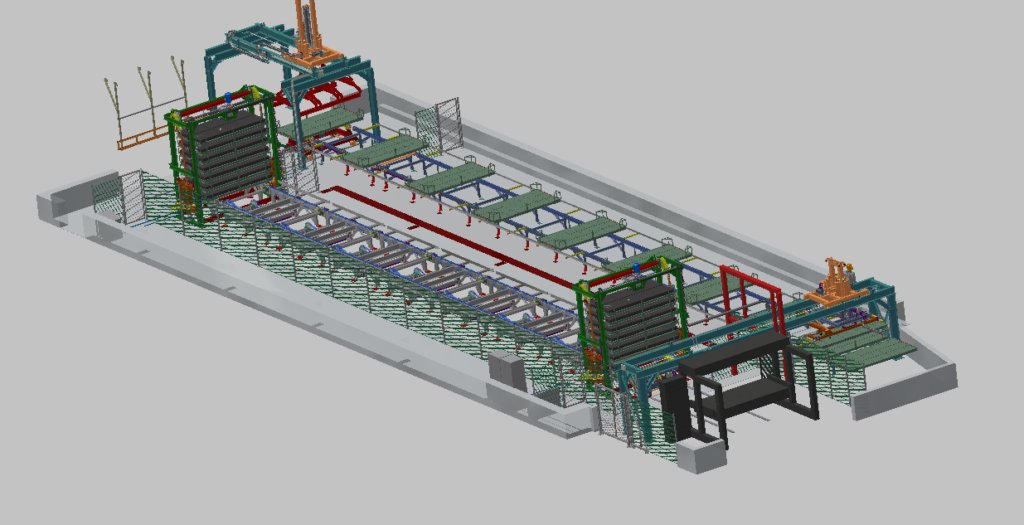

Line for the production of concrete slabs

Tytan Technik has developed and built an innovative, globally unique line for the production of concrete slabs in sizes 300x150x15 cm and 100x75x10 cm.

This production line allows manufacturers to significantly improve and automate the production process, ensuring high repeatability, quality, and efficiency.

Advantages of the Concrete Slab Production Line:

-

High production capacity – up to 100 slabs of 300x150x15 cm or 600 slabs of 100x75x10 cm per day.

-

Production under a roof – unaffected by sun or rain, allowing reduced cement consumption.

-

Stacking of products – significantly reduces the space needed for production and curing.

-

Homogeneous pre-curing atmosphere – ensures even curing and optimal quality of concrete slabs.

-

No strict requirement for consecutive concrete batch consistency – increases flexibility in production.

-

Excellent repeatability and strength – high quality products with consistent results.

-

Transport pallet forming – slabs do not fall out of molds during rotation, reducing defects.

-

Minimal scrap and waste – production and packaging process is highly efficient.

-

Stationary and walking press modes – the machine can operate on the line or move to produce other products in the yard.

Line Visualization